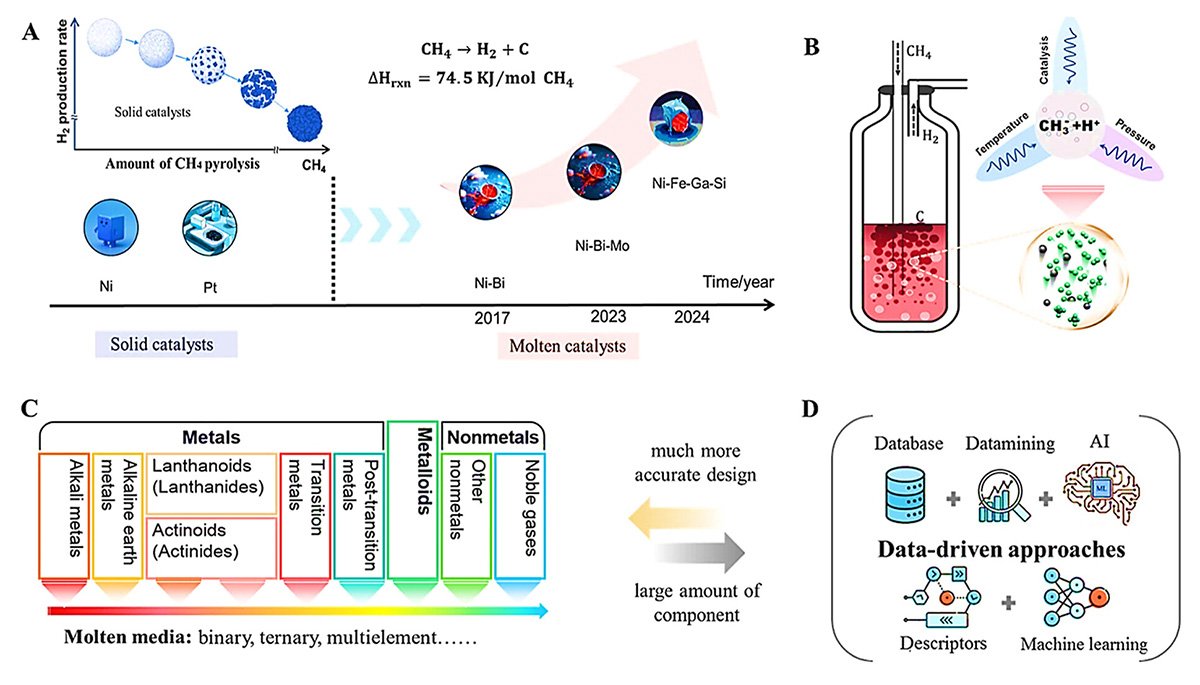

Methane (CH4) pyrolysis, a reaction that produces hydrogen without emitting carbon dioxide, often utilizes molten media catalysts. A recent research paper has explored how artificial intelligence and machine learning are helping scientists identify these catalysts more efficiently.

Details were published in the journal ACS catalysis on June 11, 2025.

The industrial implementation of methane pyrolysis via molten media catalysis has been stymied by the need for extremely high temperatures, raising energy costs and technical barriers.

Recent breakthroughs have shown that multicomponent molten systems, including binary, ternary, and quaternary mixtures, can enable CH4 pyrolysis at more moderate temperatures. Yet, designing such systems is challenging due to the vast number of elemental combinations and the inherent atomic disorder within molten catalysts.

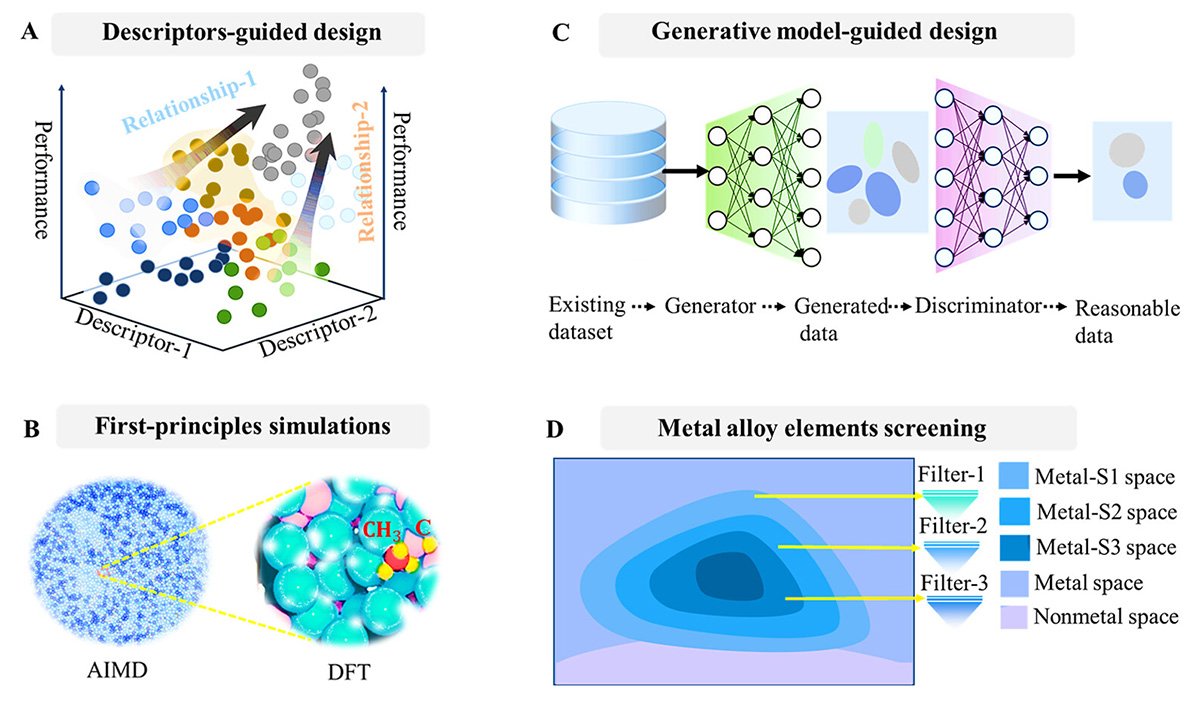

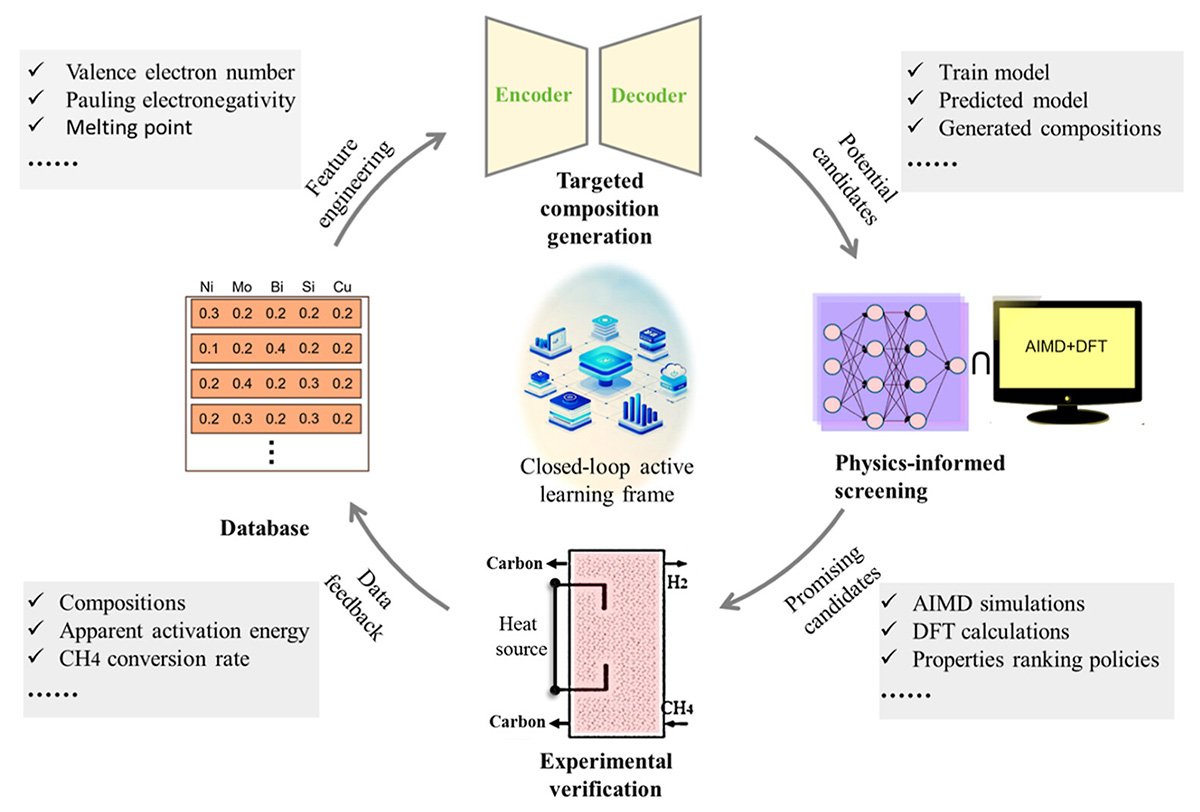

"To systematically explore the design space of multicomponent molten catalysts, data-driven approaches guided by AI offer significant advantages over traditional trial-and-error experimentation," says Hao Li, a professor from Tohoku University's Advanced Institute for Materials Research (WPI-AIMR) who led the study. "We propose descriptor-guided, generative model-guided, and active learning-guided strategies to accelerate catalyst discovery."

The research highlights how descriptor-guided design can identify key physicochemical properties influencing catalyst performance, while generative models can suggest novel compositions for experimental validation. Active learning frameworks, integrating continuous feedback from experiments, can further refine predictions to target optimal catalyst candidates.

"Our next steps involve developing machine learning-based molten catalyst models using high-quality training data," Li explains. "We also aim to build self-driven data acquisition platforms and advance multiscale simulation methods to better understand real reaction environments."

The team emphasizes the importance of large-scale experimental databases to support data-driven catalyst design. The Digital Catalysis Platform (DigCat), developed by the Hao Li Lab, is cited as the largest catalysis database and the first digital platform of its kind globally.

Li concludes, "By combining AI, machine learning, and experimental data, we hope to overcome the design bottlenecks of molten media catalysts and accelerate the industrialization of methane pyrolysis technologies."

- Publication Details:

Title: Data-Driven Strategies for Designing Multicomponent Molten Catalysts to Accelerate the Industrialization of Methane Pyrolysis

Authors: Yuanzheng Chen, Xuxuan Huang, Yangdong He, Qian Liu, Junmei Du, Wei Yang, Wenhan Wang, Di Zhang, Xue Jia, Hongyan Wang, Yongliang Tang, Qingkai Yu, Seok Ki Kim, and Hao Li

Journal: ACS Catalysis

DOI: doi.org/10.1021/acscatal.5c02415

Contact:

Hao Li,

Advanced Institute for Materials Research (WPI-AIMR), Tohoku University

Graduate School of Engineering, Tohoku University

Email: li.hao.b8 tohoku.ac.jp

tohoku.ac.jp

Website: https://www.li-lab-cat-design.com/