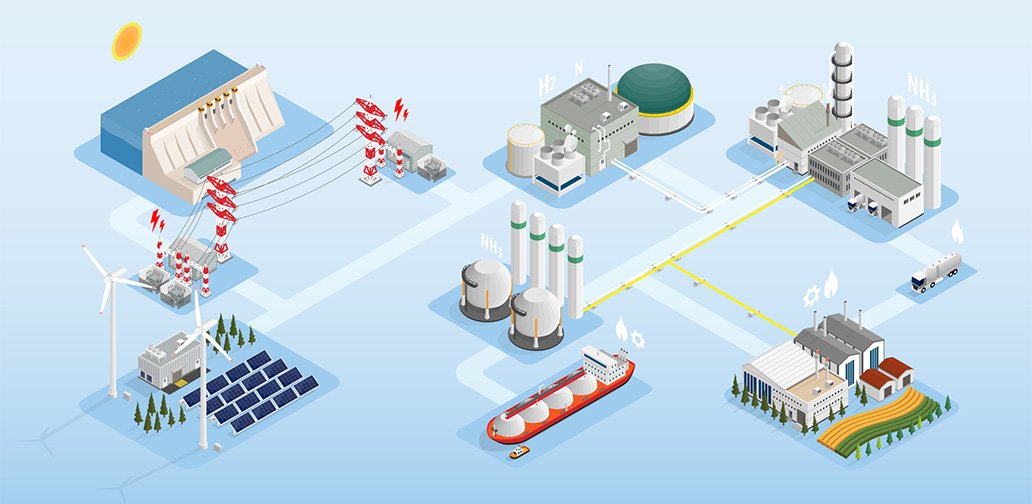

When the current method for producing something is estimated to consume a staggering 1-2% of the annual global energy supply, it means we need to make a change. The Haber-Bosch process produces ample amounts of ammonia (NH3) - a valuable chemical compound that has a wide array of uses in fields such as agriculture, technology, and pharmaceuticals - while consuming a lot of energy.

A research team at Tohoku University has made a significant contribution to an alternate method for converting harmful nitrate pollutants in water into ammonia, addressing both environmental and energy challenges. By utilizing NiCuFe-layered double hydroxide (LDH) catalysts, the study provides an efficient method for cleaning contaminated water. This means cleaner water, reduced pollution, and more sustainable fertilizer and energy resources, which are directly beneficial to public health, food security, and climate protection.

The Haber-Bosch process currently produces almost all of the industrially produced ammonia in the world, but it has major downsides. Not only does it consume an exorbitant amount of energy, the process also releases carbon dioxide emissions as a byproduct, making it even more taxing on the environment. The electrocatalytic nitrate (NO3−) reduction reaction (NitRR) is an alternative option to produce ammonia that has existed for a while, but it never caught on due to being slow and inefficient. However, researchers at Tohoku University's Advanced Institute for Materials Research (WPI-AIMR) found a method to overcome this.

"We created NiCuFe-LDH nanosheets with Ni and Cu sites to help with electroreduction," explains Professor Hao Li (WPI-AIMR). "The NitRR went from being too inefficient to even consider, to a Faradaic efficiency of 94.8%."

They used computational and theoretical analyses to explain the mechanism for this reaction, which involves the added Cu and Ni sites as the stars of the show. Furthermore, they tested a Zn-NO3− battery utilizing NiCuFe-LDH nanosheets to demonstrate its actual efficacy. It performed very well, with a Faradaic efficiency of 85.8%, a high yield of ammonia, and a power density so remarkable that it outperformed most previous reports (12.4 mW cm−2).

The next steps for this project will focus on scaling up and deepening mechanistic understanding. On the practical side, the catalyst performance needs to be validated in real nitrate-contaminated water systems and under continuous-flow reactor conditions to demonstrate industrial feasibility.

The findings were published in Advanced Functional Materials on September 4, 2025.

- Publication Details:

Title: Modulating Surface-Active Hydrogen for Facilitating Nitrate-to-Ammonia Electroreduction on Layered Double Hydroxides Nanosheets

Authors: Bin Liu, Yuan Wang, Huiming Wen, Yuchen Wang, Heng Liu, Bo Da, Ke Li, Hao Luo, Hao Li and Kai Yan

Journal: Advanced Functional Materials

DOI: https://doi.org/10.1002/adfm.202519238

Contact:

Hao Li

Advanced Institute for Materials Research (WPI-AIMR), Tohoku University

Email: li.hao.b8 tohoku.ac.jp

tohoku.ac.jp

Website: https://www.li-lab-cat-design.com/