The Tohoku University Engineering Summer Programme (TESP) was held this year after a three-year hiatus due to the COVID-19 pandemic. The programme's return attracted more than 40 participants from universities around the world.

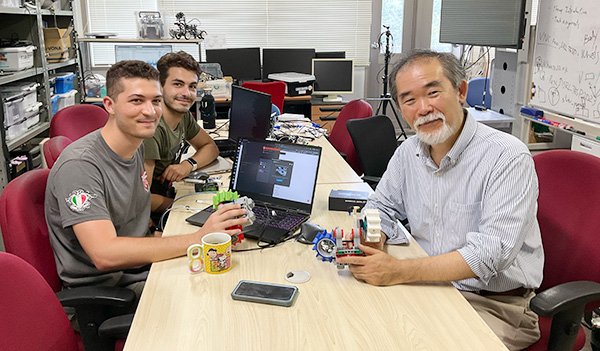

Anchored by Robotics, led by Professor Kazuya Yoshida, this year's programme also featured courses from two other prominent divisions within the Graduate School of Engineering - Structural Materials Engineering (SMEC) and Bio-materials Engineering (BMEC).

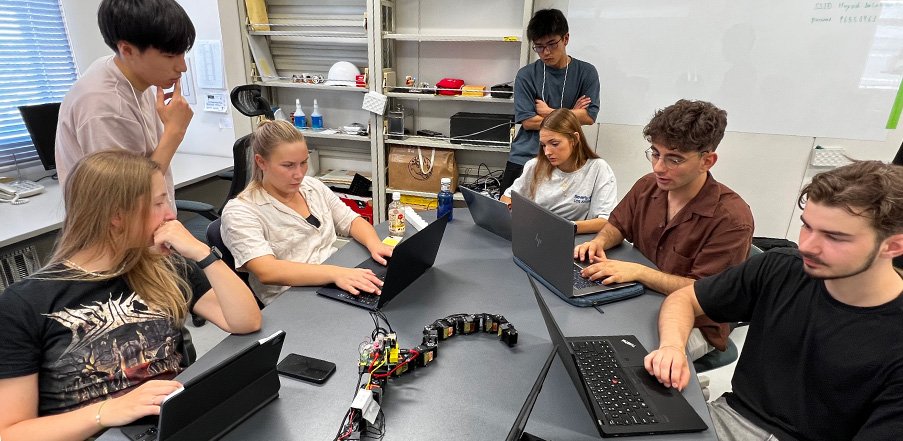

The Robotics Course had a curriculum designed to give participants an overview of the different applications and research being developed at Tohoku University. These include field, space and rescue robotics, medical robotics, human-robot interaction and haptic interface.

"In my lecture on haptic interfaces, I introduced how the sense of touch can be presented in robot teleoperation and virtual reality," said Associate Professor Masashi Konyo. "In the lab activities, the students developed a prototype based on their idea of a haptic interface that records the sensation of walking, and reproduces it in a VR system."

Konyo noted that the lab activities were lively as the students enjoyed the in-person interaction. "It was a good opportunity not just for the TESP participants but also for the Tohoku University students in our labs to learn about what other engineering students are doing in other parts of the world."

Yoshida said that he definitely noticed a shift in interest towards more AI-oriented topics and human-oriented applications in the robotics programme this year.

"In the hands-on laboratory activities, I also observed a significant update in both hardware and software environments to build advanced robots," he said. "It is now much easier for students to access up-to-date technologies, and test their ideas with prototype models more quickly than in the past. The world is indeed progressing at an incredible pace!"

The Structural Materials Engineering Course (SMEC), led by Professor Kyosuke Yoshimi, featured alloy design and Thermo-Calc training, alloy synthesis by arc-melting, and specimen preparation training.

In the labs, the students made real alloys using the melting and casting method based on phase diagrams. "The students were divided into three groups - the iron group, the nickel group and the titanium group - and we gave them about 10 days to complete this process," said Yoshimi. "Then we held a contest to determine which alloy was the most attractive as a structural material. The students had to identify the phases, density, microstructure, hardness, strength and ductility of the alloys designed."

"I believe that Japan has an advantage when it comes to materials research because students conduct real experiments from the graduation research stage, and this helps to improve their experimental skills and refine their research sense," said Yoshimi. "It's an original style of research that is the foundation of the saying 'Made in Japan.' If the TESP participants found it interesting, I hope that they will come back and study with us."

The Bio-materials Engineering Course (BMEC) aimed to give students a better understanding of the development of biomaterials with clinical applications from a viewpoint of polymer chemistry and cell biology.

"We provided explanations of polymeric biomaterials, drug delivery systems, tissue engineering, regenerative medicine, and 3D bioprinting, to help them understand how to apply biomaterials to patient care, as well as fundamental medical research," said Professor Masaya Yamamoto.

The students also had the opportunity to use a variety of cutting-edge instruments in the laboratories to learn about current research topics in 3D bioprinting.

Away from the classrooms and labs, there were workshops on traditional Japanese culture such as tea ceremony and kimono dressing. There was also a field trip to Yamadera and Mount Zao.

BMEC and SMEC participants toured a swordsmith's workshop to see how Japanese swords are made, and studied the role that materials play in space at the JAXA Space Center in Kakuda. They also visited the Kosaka Smelter and Refinery in Akita Prefecture to see first-hand the workings of a metal recycling plant.

"The excursions provided valuable experiences that reinforced some of the things we talked about in the lectures," said Yamamoto. "It was also an important opportunity for the participants of the different courses to get to know each other and be part of a growing network."

Contact:

Tohoku University Engineering Summer Programme (TESP)

Division of International Education & Exchange, School of Engineering

Tel: +81 22-795-7996

Email: tesp grp.tohoku.ac.jp

grp.tohoku.ac.jp