Precise graphene nanoribbons (GNRs) with periodic regions of zigzag-edge were produced using a novel bottom-up fabrication method by Prof. Patrick Han and Prof. Taro Hitosugi, in collaboration with Prof. Naoki Asao, Prof. Kazuto Akagi, and Prof. Paul S. Weiss at the Advanced Institute for Materials Research (AIMR), Tohoku University. This fabrication method, which also controls GNR growth direction and length distribution, maybe a stepping stone towards future graphene-device fabrication by self-assembly.

Graphene, a stable single-atomic layer of carbon atoms in a honey-comb lattice (Figure 1a), promises to be a revolutionary material for making next-generation high-speed transistors. One ongoing strategy focuses on using graphene edge conformations as a means to control the electronic and magnetic properties of GNR structures. However, to date, neither lithography (top-down), nor molecular-assemblies (bottom-up) have produced GNRs with defect-free zigzag edges. In this work, the research team at AIMR deposited a precursor molecule (Figure 1b), known to form armchair-GNR, onto a Cu substrate (Figure 1c). Utilizing properties specific to this substrate, Han et al. changed the assembly chemistry to produce GNRs with periodic zigzag features instead (Figure 1d). The new edge configuration may contribute to the design and creation of future electronic and spintronic devices. These results will be published in the upcoming issue of the journal ACS Nano.

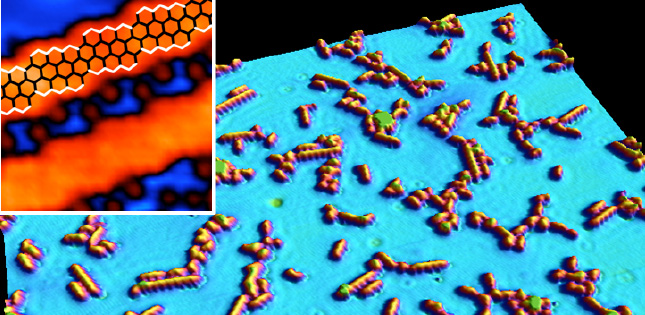

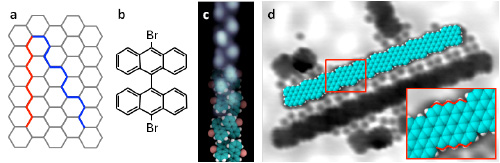

Figure 1.

(a) Graphene honey-comb and the zigzag and armchair edges. (b) Precursor molecule. (c) and (d) show the scanning tunneling microscope images of a chain of precursor molecules (3 nm × 9 nm), and of a GNR cluster after polymerization (13 nm × 9 nm), respectively. The inset in (d) highlights the zigzag edges.

Introduction

Graphene is an extraordinary material because of its low dimensionality, high stability, high strength, and high charge-carrier mobility. Graphene's properties are also predicted to be directly controllable by its structure. For example, recent works have demonstrated that the bandgap of armchair GNRs is controlled by the ribbon width. However, the property-tailoring capabilities of other edge conformations (e.g., the zigzag edge is predicted by theory to have magnetic properties) have not been tested, because their defect-free fabrication remains a major challenge.

Research content

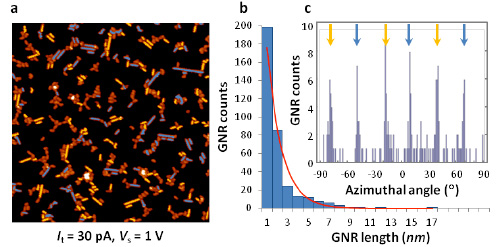

In this work, Han et al. developed a substrate-directed molecular assembly method to fabricate defect-free GNRs with periodic zigzag-edge structures--a first-time demonstration that contiguous zigzag edges can be fabricated by bottom-up methods (Figures 1d and 2a). Digital image processing was used to characterize both the GNR length distribution and their preferred surface growth directions (Figures 2b and 2c). Combining these measurements with density functional theory, the authors demonstrated that this method produces GNRs whose length distributions and surface growth directions are directly controlled by the assembly mechanism.

Figure 2.

(a) Topographic STM image of GNRs on Cu(111) (100 nm × 100 nm). (b) Length distribution of the GNRs in (a). (c) Surface growth-direction distribution GNRs in (a) showing six preferred directions.

Future visions

This work demonstrates that properties of reactive surfaces can be directly invoked to dictate the edge configurations of self-assembled graphene product: it is a stepping stone towards the bottom-up defect-free fabrication of proper zigzag-edge GNRs. Moreover, the GNRs fabricated using this method will be used to test the property-tailoring effects of their edge configuration. Finally, the mechanism of this molecular assembly can be exploited to test new ways of making graphene interconnects and other graphene electronic/spintronic devices. For example, the control of GNR length and growth direction makes this fabrication method an ideal candidate for self-assembling graphene devices. With this control, single graphene connections between two prefabricated electrodes can be attempted, where other bottom-up methods would results in unknown number of connections.

Acknowledgement

We thank Prof. Alex L. Shluger for insightful discussions. The computation was done using the HA8000 system of RIIT, Kyushu University. This work was supported by the World Premier International Research Center Initiative (WPI) promoted by the Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan.

Publication Information

Patrick Han, Kazuto Akagi, Filippo Federici Canova, Hirotaka Mutoh, Susumu Shiraki, Katsuya Iwaya, Paul S. Weiss, Naoki Asao, Taro Hitosugi, "Bottom-Up Graphene-Nanoribbon Fabrication Reveals Chiral Edges and Enantioselectivity", ACS Nano, 2014, in press (DOI: 10.1021/nn5028642).

About AIMR

-

The Advanced Institute for Materials Research (AIMR) at Tohoku University is one of nine World Premier International Research Center Initiative (WPI) Program established with the support of the Japanese Ministry of Education, Culture, Sports, Science and Technology (MEXT), aimed at developing world-class research bases in Japan. After its establishment in 2007, AIMR has been active in conducting research activities and creating new systems in order to become a global center for materials science. Since 2012, AIMR has also been conducting fundamental research by finding connections between materials science and mathematics.

Website: http://www.wpi-aimr.tohoku.ac.jp/en/index.html

Contact:

(about Research)

Prof. Patrick Han

Email: pxh wpi-aimr.tohoku.ac.jp

wpi-aimr.tohoku.ac.jp

TEL: +81-22-217-6170

(about Public Relations)

Public Relations & Outreach office (Yasufumi NAKAMICHI)

Email: outreach wpi-aimr.tohoku.ac.jp

wpi-aimr.tohoku.ac.jp

TEL: +81-22-217-6146